ICD/ITKE – RESEARCH PAVILION

2012

Institute for Computational Design (ICD) –

Prof. Achim Menges

Institute of Building Structures and Structural Design (ITKE) –

Prof. Dr.-Ing. Jan Knippers

In November 2012 the Institute for Computational Design (ICD) and the Institute of Building Structures and Structural Design (ITKE) at the University of Stuttgart have completed a research pavilion that is entirely robotically fabricated from carbon and glass fibre composites. This interdisciplinary project, conducted by architectural and engineering researchers of both institutes together with students of the faculty and in collaboration with biologists of the University of Tübingen, investigates the possible interrelation between biomimetic design strategies and novel processes of robotic production. The research focused on the material and morphological principles of arthropods’ exoskeletons as a source of exploration for a new composite construction paradigm in architecture.

BIOLOGICAL MODEL

Following a “bottom-up” approach, a wide range of different subtypes of invertebrates were initially investigated in regards to the material anisotropy and functional morphology of arthropods. The observed biological principles were analysed and abstracted in order to be subsequently transferred into viable design principles for architectural applications. The exoskeleton of the lobster (Homarus americanus) was analysed in greater detail for its local material differentiation, which finally served as the biological role model of the project.

TRANSFER DESIGN PRINCIPLES

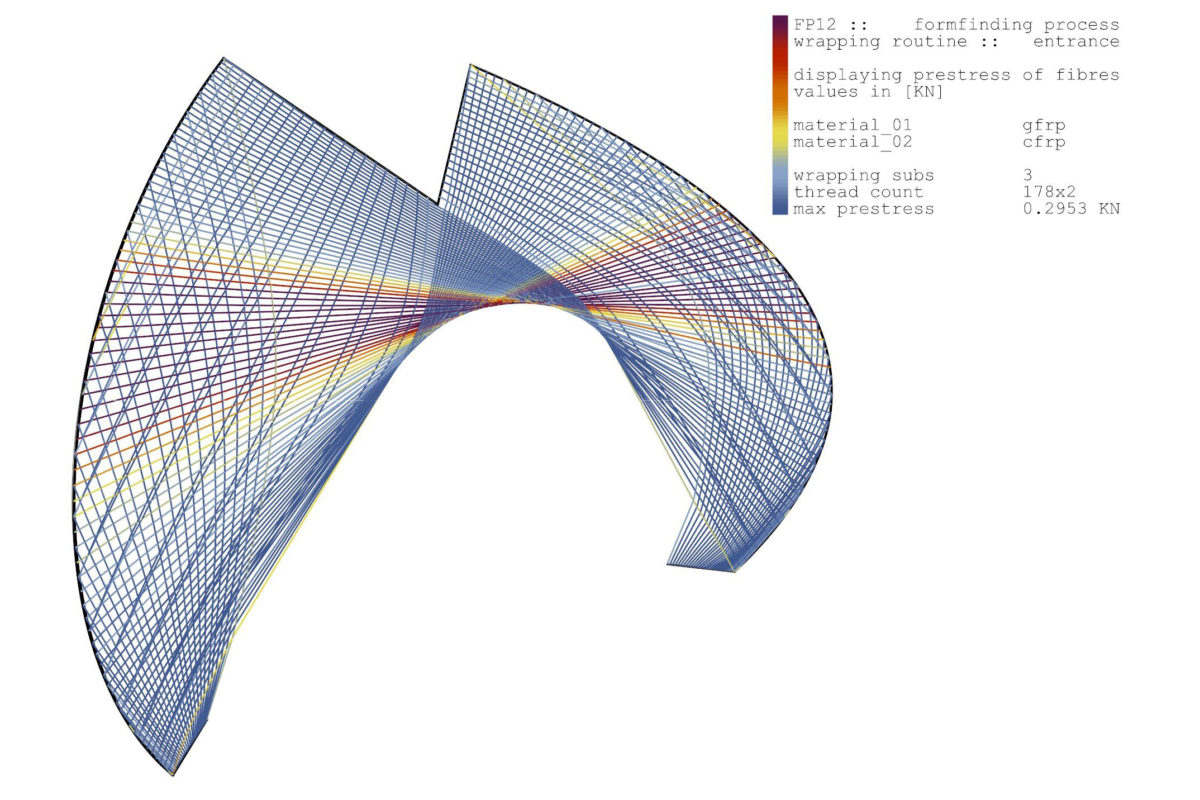

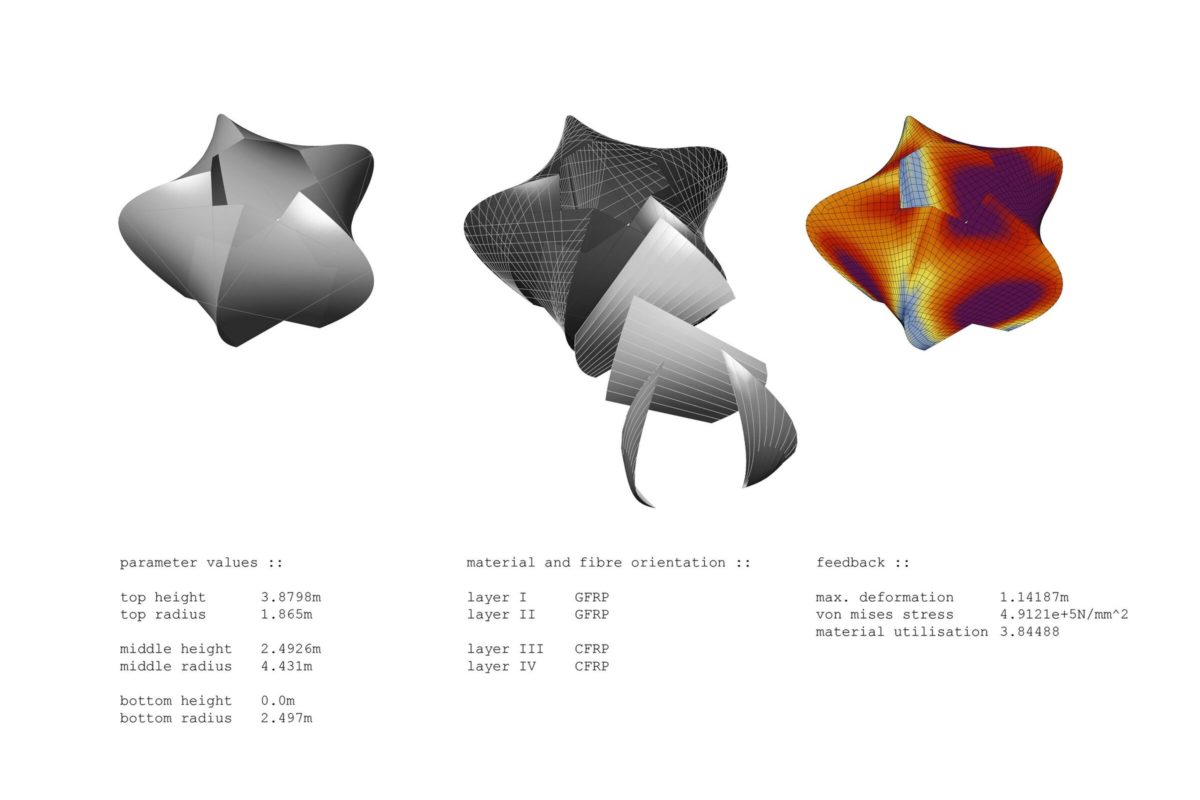

In collaboration with the biologists, the fibre orientation, fibre arrangement and associated layer thickness and stiffness gradients in the exoskeleton of the lobster were carefully investigated. The high efficiency and functional variation of the cuticle is due to a specific combination of exoskeletal form, fibre orientation and matrix. These principles were applied to the design of a robotically fabricated shell structure based on a fibre composite system in which the resin-saturated glass and carbon fibres were continuously laid by a robot, resulting in a compounded structure with custom fibre orientation.

COMPUTATIONAL DESIGN AND ROBOTIC PRODUCTION

The robotic fabrication of the research pavilion was performed on-site in a purpose-built, weatherproof manufacturing environment by a 6-axis robot coupled with an external seventh axis. Placed on a 2m high pedestal and reaching an overall working span and height of 4m, the robot placed the fibres on the temporary steel frame, which was actuated in a circular movement by the robotically controlled turntable. As part of the fabrication process the fibres were saturated with resin while running through a resin bath directly prior to the robotic placement. This specific setup made it possible to achieve a structure of approximately 8.0m in diameter and 3.5m height by continuously winding more than 60 kilometres of fibre rovings. The parametric definition of the winding motion paths in relation to the digital geometry model, the robotic motion planning including mathematical coupling with the external axis, as well as the generation of robot control code itself could be implemented in a custom-developed design and manufacturing integrated environment. After completion of the robotic filament winding process and the subsequent tempering of the fibre-resin composite, the temporary steel frame could be disassembled and removed. The remaining, extremely thin shell of just 4mm thickness for a total weight of 320Kg constitutes an automatically fabricated, but locally differentiated structure.

Images © ICD/ITKE

PROJECT TEAM

Institute for Computational Design (ICD)

Prof. Achim Menges

Institute of Building Structures and Structural Design (ITKE) –

Prof. Dr.-Ing. Jan Knippers

CONCEPT DEVELOPMENT

Manuel Schloz,

Jakob Weigele

SYSTEM DEVELOPMENT & REALIZATION

Sarah Haase, Markus Mittner,

Josephine Ross, Manuel Schloz,

Jonas Unger, Simone Vielhuber,

Franziska Weidemann, Jakob Weigele,

Natthida Wiwatwicha

SCIENTIFIC DEVELOPMENT & PROJECT MANAGEMENT

Riccardo La Magna (structural design),

Steffen Reichert (detailing),

Tobias Schwinn (robotic fabrication),

Frédéric Waimer (structural design)